How to

From PlcWiki

Issues

To bypass these issues temporarily one of the emergency barcodes PLCIL or PLCABCNEXT can be used.

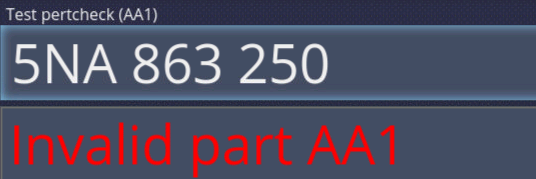

Invalid part

When invalid part is scanned red alert appears in log frame …

Solution: - Scan correct part. - “Part equivalence” can be used in case that part is equivalent to requested. Barcode PLC temporarily can be used in emergency. Alternatively, Part equivalence module can be used.

Unknown barcode PIC:

Client doesn’t recognize scanned barcode at all. Wasn’t able to assign input to any operation.

Solution: Ensure that part being used is correct part. Most probably this barcode is not covered by SelectPattern in operations’ configuration. Has to be fixed in Clea.

Invalid (damaged/missing) barcode

PIC  If a barcode is unreadable but it’s a correct part, a special barcode can be scanned to continue the operation.

If a barcode is unreadable but it’s a correct part, a special barcode can be scanned to continue the operation.

Solution: - Ensure that it is correct part visually, scan emergency barcode PLCIL.

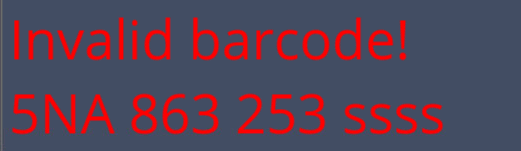

Unable to convert a barcode PIC: unable to convert …

Client recognized input and assigned to operation, but can’t internally translate input to part number.

Solution: - Has to be fixed in Clea in Quality condition configuration.

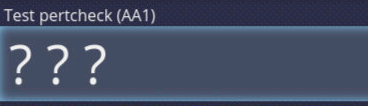

Question marks in operations’ frame

Operation is requested, but not appropriate part was found in incoming data.

Solution: - Has to be fixed in Clea in Quality condition configuration.