CLEVER AutoStart

From PlcWiki

| Line 70: | Line 70: | ||

=='''3.1. Workplace parameters'''== | =='''3.1. Workplace parameters'''== | ||

| + | |||

| + | 1. | ||

| + | 2. | ||

| + | 3. | ||

| + | 3.1 | ||

| + | =='''3.1.1. Product ID'''== | ||

| + | |||

| + | This setting is specific for each plant and depends on a pattern of the product ID. It needs to accept the RFID tag suffix: | ||

| + | |||

| + | {| class="wikitable" border="1" cellpadding="2" | ||

| + | ! Parameter | ||

| + | ! Value | ||

| + | |- | ||

| + | | Product ID Select Pattern | ||

| + | | ^(<current settings>)(RFID_.+)?$ | ||

| + | For example | ||

| + | ^(3120[12]\d{9})(RFID_.+)?$ | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | =='''3.1.2. Next Product'''== | ||

| + | In case the RFID tag comes to the reader earlier, then the previous product is finished, it is necessary to store the product id to a queue. The queued product ID is taken from the queue, when the previous product is finished. This is the moment, when the start signal is sent to the smart watch in this case. | ||

| + | Because the product ID needs to be queued only in case it is received from the RFID tag conversion, the queueing is defined on the RFID device: | ||

| + | |||

| + | workplace.device.rfid_identcontrol.settings.NextProductID.Queued = true | ||

| + | |||

| + | If the product ID is scanned manually for an assembly sheet, it mustn’t be queued: | ||

| + | |||

| + | |||

| + | {| class="wikitable" border="1" cellpadding="2" | ||

| + | ! Parameter | ||

| + | ! Value | ||

| + | |- | ||

| + | | Queue Next Product ID | ||

| + | | No | ||

| + | |- | ||

| + | |} | ||

Revision as of 11:25, 27 January 2021

Contents |

(Automated start using RFID tags and smart watch confirmation)

Implementation documentation

v. 1.2 - 2021-01-25

version note: Workplace tags implemented

1. General description

The main purpose of the AutoStart feature is to start a product on a workplace without its scanning from a paper BoM, but using a smart watch for the confirmation, that an operator registered the new product and is going to work on it. The product is registered on a workplace by a reading of an RFID tag by an RFID reader (antenna). When the tag is read, the CLEVER Client sends a notification to a smart watch and is waiting for the confirmation back. The product is announced to an operator on the smart watch display and by a smart watch vibration. The operator touches the smart watch to confirm his readiness. The smart watch sends a confirmation back to CLEVER Client and the product is started.

2. Marriage workplace

In the very beginning of the assembly line, the marriage workplace needs to be configured. It assigns the RFID tag (mounted on each trolley) to the product (cockpit ID). That workplace is configured in a standard CLEVER Client.

See an important alternative mentioned at the end of this chapter.

An operator scans the paper BoM to start the product (a standard feature). When the RFID tag is read by a reader, the tag ID is assigned to the started product. An operation “RFID reading” (type Serial) is needed there.

To avoid a situation, when the operator scans the product ID latter than the RFID tag comes to the reader, it is possible to buffer that operation. In that case the order of these events can be opposite. At first the tag is read (and its ID is buffered) and then the operator scans the product ID. The tag ID is taken from the buffer and assigned to the product.

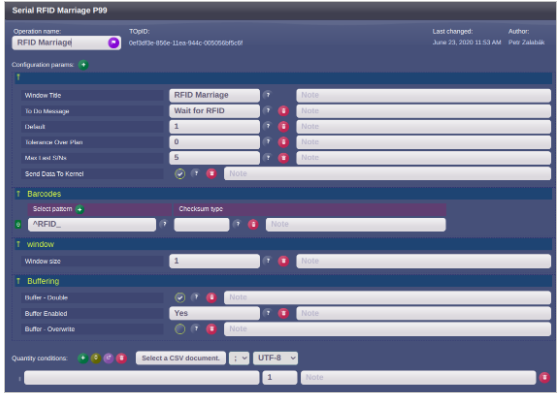

Following parameters are important for the RFID reading (marriage) operation:

| Parameter | Value |

|---|---|

| Send Data To Kernel | Yes |

| Buffer Enabled | Yes |

| Tolerance Over Plan | 0 |

| Default quantity condition | 1 |

Example of the Clea settings of the marriage operation:

IMPORTANT: The marriage workplace plays an absolutely key role for the entire functionality of the AutoStart system. The 100% reliably working process here is absolutely needed. It is necessary to focus on that workplace from a very beginning of the implementation.

IMPORTANT: The marriage workplace plays an absolutely key role for the entire functionality of the AutoStart system. The 100% reliably working process here is absolutely needed. It is necessary to focus on that workplace from a very beginning of the implementation.

ALTERNATIVE: Manual scanning of a trolley barcode instead of a RFID reading can be used for the marriage purpose as well. That way gives even a higher reliability of the marriage process. In that case, the barcode content needs to be a fixed prefix “RFID_” and then the tag RFID ID. For example “RFID_D6F92803”. The barcode format can be whichever alphanumeric code, like QR, Datamatrix, Cokde39,…

ALTERNATIVE: Manual scanning of a trolley barcode instead of a RFID reading can be used for the marriage purpose as well. That way gives even a higher reliability of the marriage process. In that case, the barcode content needs to be a fixed prefix “RFID_” and then the tag RFID ID. For example “RFID_D6F92803”. The barcode format can be whichever alphanumeric code, like QR, Datamatrix, Cokde39,…

3. Settings for CLEVER Client

CLEVER Client version required: 2101190928 or higher.

The driver RFID_IDENTCONTROL.drv is needed in the /usr/local/plc/etc/drivers folder. It is possible to update each station to the latest Client version by the following command:

yum update -y --disablerepo \* --enablerepo plc_client plc_client_bins plc_client_drivers plc_client_langs

Each workplace, which will use the AutoStart feature, needs to be configured according to following instructions. The workplaces are configured either individually, or using a workplace tags (described below).

3.1. Workplace parameters

1. 2. 3. 3.1

3.1.1. Product ID

This setting is specific for each plant and depends on a pattern of the product ID. It needs to accept the RFID tag suffix:

| Parameter | Value |

|---|---|

| Product ID Select Pattern | ^(<current settings>)(RFID_.+)?$

For example ^(3120[12]\d{9})(RFID_.+)?$ |

3.1.2. Next Product

In case the RFID tag comes to the reader earlier, then the previous product is finished, it is necessary to store the product id to a queue. The queued product ID is taken from the queue, when the previous product is finished. This is the moment, when the start signal is sent to the smart watch in this case. Because the product ID needs to be queued only in case it is received from the RFID tag conversion, the queueing is defined on the RFID device:

workplace.device.rfid_identcontrol.settings.NextProductID.Queued = true

If the product ID is scanned manually for an assembly sheet, it mustn’t be queued:

| Parameter | Value |

|---|---|

| Queue Next Product ID | No |